-

Call Us:

-

Email Us:

Industrial Equipment That Works As Hard As You Do...

ABOUT US

Panurgy Industries

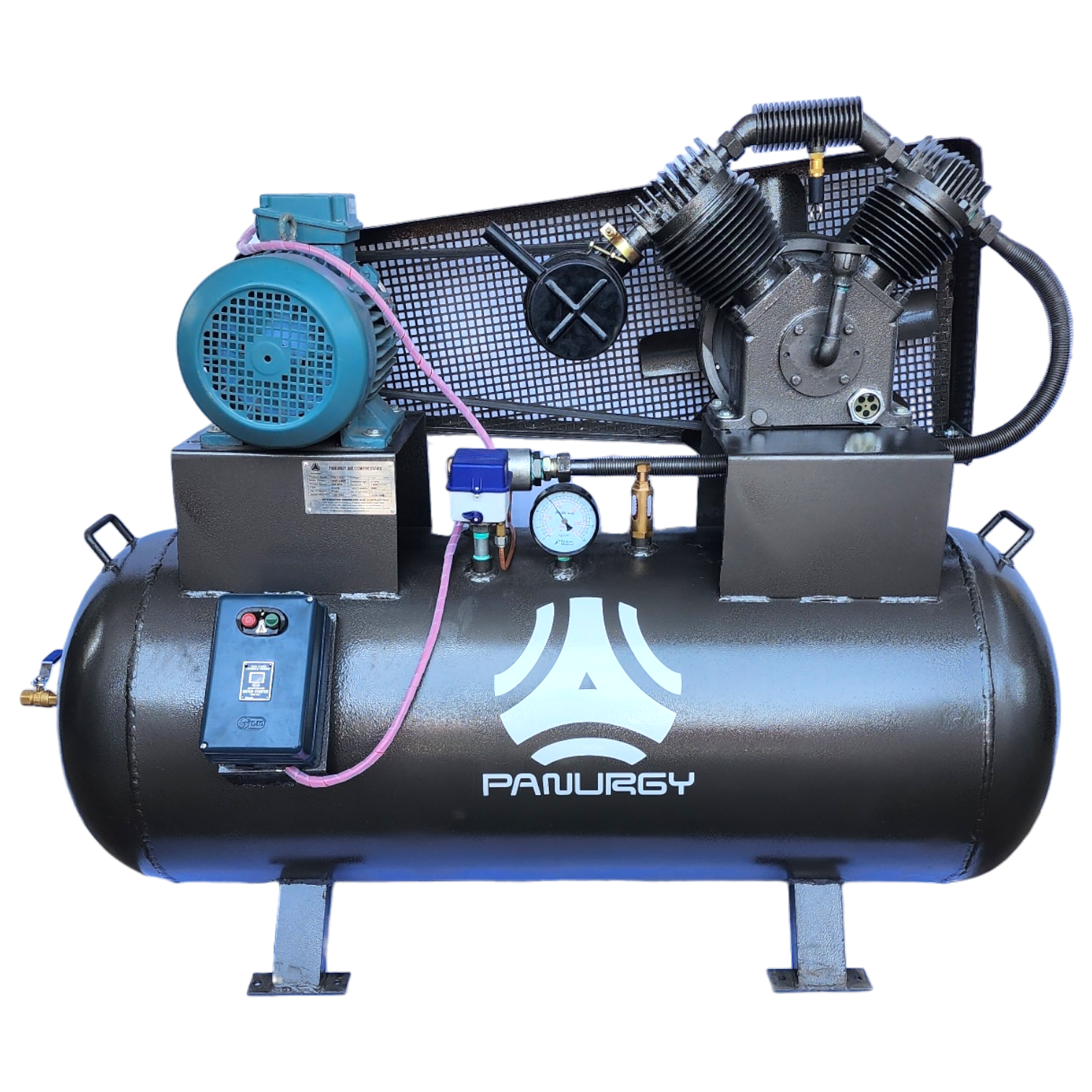

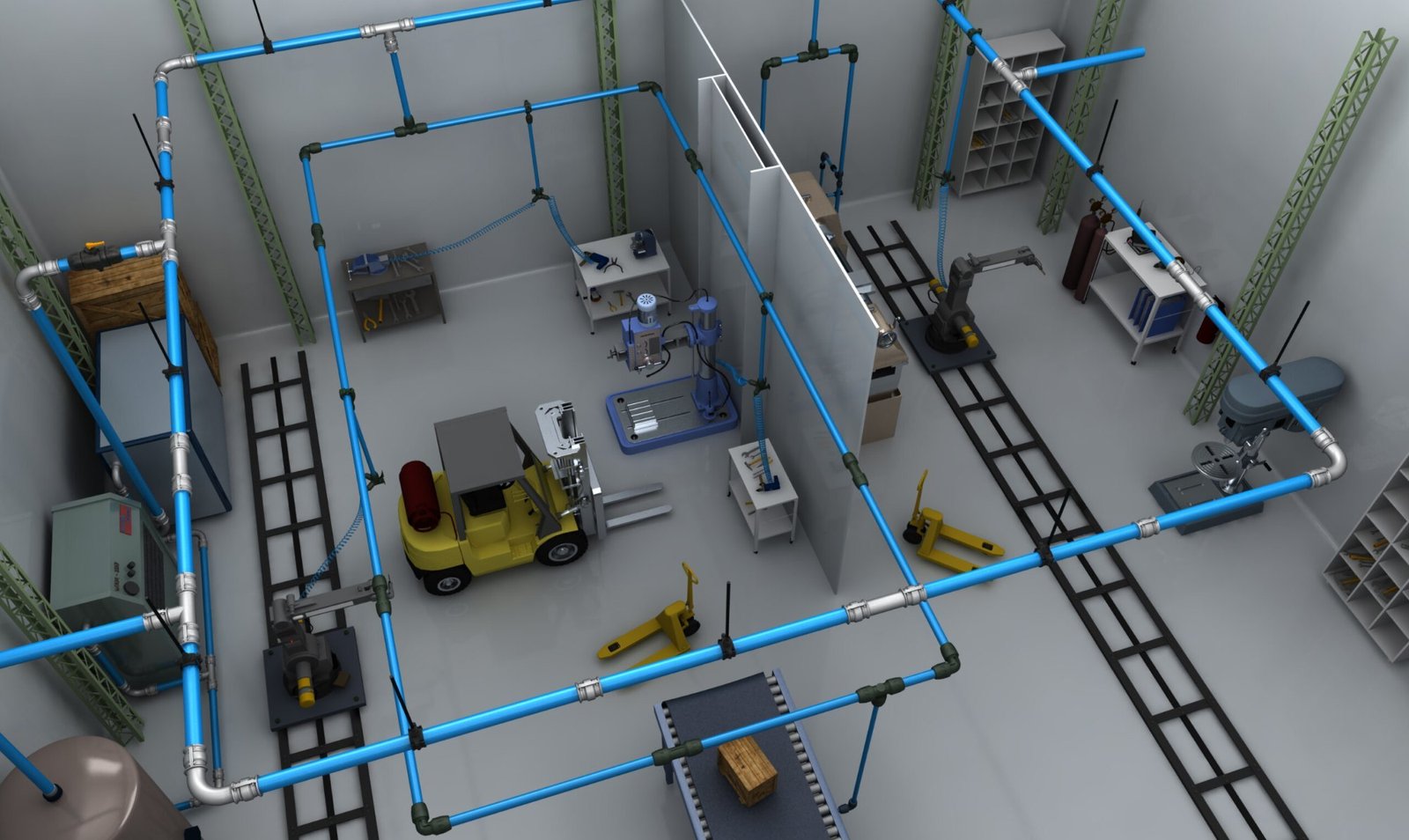

Panurgy is a leading provider of industrial solutions for businesses with Compressed Air, Dehumidification, Refrigeration, and Heat Exchange requirements. Our team of highly qualified engineers specializes in providing consultancy services to help enhance the efficiency of our clients' systems. We are committed to designing and manufacturing top-class products that meet the needs of our clients.

We offer a wide range of products and services, including Screw & Reciprocating Type Air Compressors, Refrigeration & Desiccant Type Air Dryers, Air Receivers, Compressed Air Filters, Dehumidifiers, Humidifiers, Air purifiers, Process Chillers, Cold Rooms, and Shell & Tube, Finned Tube, & Plate Type Heat Exchangers.

At Panurgy, we understand the importance of reducing costs for our clients, and therefore, our solutions are designed with a focus on efficiency and affordability. We take pride in providing top-class products and services that not only meet but exceed our clients' expectations. Our commitment to quality and customer satisfaction has helped us build long-lasting relationships with our clients.

Read MoreIndustrial Chillers

Humidity Control and Air Purification

Our Mission

Panurgy provides energy-efficient and cost-effective industrial equipment solutions that are designed to meet the industry's needs while reducing costs for our customers. Our core values of humility, adaptability, and environmental responsibility guide everything we do, and we are committed to promoting sustainability through our products and practices. Our aim is to make our equipment the backbone of the industry's drive towards a sustainable future.